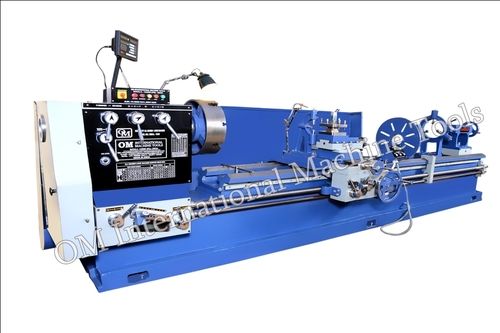

All Geared Lathe Machine

Product Details:

- Product Type Horizontal

- Material Casting Iron

- CNC Or Not Normal

- Automatic Grade Automatic

- Voltage 415 Volt Volt (v)

- Feature ECO Friendly High Performance High Efficiency

- Color Blue

All Geared Lathe Machine Price And Quantity

- 710000 INR/Unit

- 700000.00 - 765000.00 INR/Unit

- 1 Unit

All Geared Lathe Machine Product Specifications

- 1 Year

- ECO Friendly High Performance High Efficiency

- Automatic

- Blue

- Normal

- Horizontal

- Casting Iron

- 415 Volt Volt (v)

All Geared Lathe Machine Trade Information

- Ludhiana

- Letter of Credit at Sight (Sight L/C) Cash on Delivery (COD) Telegraphic Transfer (T/T) Western Union Letter of Credit (L/C) Delivery Point (DP) Cash Advance (CA) Cash in Advance (CID) Cheque

- 5 Unit Per Week

- 4 Days

- As Per Customer Requirement

- Central America North America South America Eastern Europe Western Europe Middle East Asia Australia Africa

- All India

- ISO 9001: 2015

Product Description

Being well-equipped with the latest technology machinery & equipments and supported by a team of professionals, we are engaged in manufacturing and exporting All Geared Lathe Machine. This machine is applied for cutting metal work and wood work sheets. We manufacture this machine using best quality mild steel and cast iron, sourced from trusted vendors. The machine has a oil bath system with lever type arrangement for automatic feeds. Our All Geared Lathe Machine can perform all kinds of metal turning, grooving, chamfering, knurling and facing job. We offer this machine at cost effective prices to clients.

Features:

- Easy to install

- Longer working life

- High working efficiency

|

Technical Specification |

MODEL NO |

||||||

|

OMAL 44 |

OMAL 55 |

OMAL 62 |

OMAL 65 |

OMAL 68 |

OMAL 75 |

OMAL 80 |

|

|

Bed length |

4.5 F T |

6 F T |

4.5 F T & 6 F T |

8 F T & 11 F T |

7 F T |

9 & 12 F T |

9 F T & 12 F T |

|

Width of bed |

240 MM |

242 MM |

242 MM |

280 MM |

325 MM |

325 MM |

375 MM |

|

Height of Center |

165 MM |

170 MM |

180 MM |

215 MM |

240 MM |

240 MM |

300 MM |

|

Swing Over Bed |

330 MM |

340 MM |

360 MM |

430 MM |

480 MM |

480 MM |

600 MM |

|

Swing over Slide |

170 MM |

180 MM |

200 MM |

270 MM |

275 MM |

275 MM |

390 MM |

|

Spindle Bore |

40 MM |

40 MM |

40 MM |

50 MM |

50 MM |

50 MM |

80 MM |

|

Spindle Nose |

LOO Type |

LOO Type |

LOO Type |

LOO Type |

LOO Type |

LOO Type |

LOO - Type |

|

Spindle Speed |

8 |

8 |

18 H-L |

8 |

18 H-L |

18 H-L |

16 H-L |

|

RPM |

60 - 1025 |

60 - 1025 |

30 - 1550 |

60 - 1025 |

30 - 1550 |

30 - 1550 |

30 - 1050 |

|

Cross Slide Travel |

175 MM |

180 MM |

185 MM |

220 MM |

260 MM |

260 MM |

325 MM |

|

Top Slide Travel |

125 MM |

125 MM |

125 MM |

130 MM |

150 MM |

150 MM |

150 MM |

|

Tail Stock Sleeve |

MT 3 |

MT 3 |

MT 3 |

MT 3 |

MT 4 |

MT 4 |

MT 4 |

|

Quill Dia. / Travel |

50 / 125 |

50 / 125 |

50 / 125 |

50 / 125 |

75 / 150 |

75 / 150 |

75 / 150 |

|

Tool Shank Section |

20 x 20 MM |

20 x 20 MM |

20 x 20 MM |

20 x 20 MM |

25 x 25 MM |

25 x 25 MM |

25 x 25 MM |

|

Feeds Longitudinal |

No. 40/. 002-1 |

No.40/. 002-1 |

No.40/. 002-1 |

No.40/. 002-1 |

No.40/. 002-1 |

No.40/. 002-1 |

No.40/. 002-1 |

|

Feeds Transverse |

No.40/.005-0. 025 |

No.40/.005-0. 025 |

No.40/.005-0. 025 |

No.40/.005-0. 025 |

No.40/.005-0. 025 |

No.40/.005-0. 025 |

No.40/.005-0. 025 |

|

Metric Thread |

40/0.4-7mm |

40/0.4-7mm |

40/0.4-7mm |

40/0.4-7mm |

40/0.4-7mm |

40/0.4-7mm |

40/0.4-7mm |

|

Thread Per Inch |

45/70-4 TPI |

45/70-4 TPI |

45/70-4 TPI |

45/70-4 TPI |

45/70-4 TPI |

45/70-4 TPI |

45/70-4 TPI |

|

Lead Screw |

4 TPI |

4 TPI |

4 TPI |

4 TPI |

4 TPI |

4 TPI |

4 TPI |

|

Admit Between Centre |

600 MM |

750 / 1000 MM |

750 / 1000 MM |

1500/2500 MM |

1000 MM |

1600/2500 MM |

1500/2500 MM |

|

H.P Required |

1.5 KW (2 H.P) |

1.5 KW (2 H.P) |

1.5 KW (2 H.P) |

2.25 KW (3 H.P) |

3.7 KW (5 H.P) |

3.7 KW (5 H.P) |

3.7 KW (5 H.P) |

|

Weight Apprx. |

550 KG |

750 / 850 KG |

750 / 850 KG |

1200/1500 KG |

1350 KG |

1500/1800 KG |

1900/2300 KG |

| STANDARD ACCESSORIES | EXTRA ACCESSORIES | |

| STEADY REST | FOUR JAWS INDEPENDENT CHUCK | TAPPER TURNING ATTACHMENT |

| FOLLOW REST | THREE JAWS SELF CENTERING CHUCK | TOOL POST GRINDER |

| FACE PLATE | ELECTRIC MOTOR | MACHINE LAMP |

| MOTOR PLATE | STARTER | OIL CAN |

| DOG CHUCK PLATE | SET VEE BELTS | SPLASH GUARD |

| CHANGE GEAR SET | MOTOR PULLY | MOTOR GUARD |

| COOLANT PUMP WITH TANK & ASSEMBLY | DEAD CENTRE | |

| SERVICE TOOLS | ||

Other Products in 'All Gear Head Lathe Machine' category

|

OM INTERNATIONAL MACHINE TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS